What Is a Common Mistake a Sealcoating Contractor Might Make When Preparing the Mix?

The sealcoating companies that manufacture the concentrated sealants that contractors use provide what are essentially mixing recipes. These recipes specify how much of each ingredient the contractor should add to create a liquid seal coating. The most common mistake that a sealcoating contractor might make is to not follow the mixing recipe. For example, when sealcoating parking lots, a contractor might reduce the sand in the mix to increase the water. The product appears to cover more pavement, but it is likely too thin to provide any significant benefit. Furthermore, sand is important for parking lot sealcoating in Austin for several reasons, including enhancing traction.

What Are Two Pavement Preparation Mistakes an Austin Sealcoating Contractor Might Make?

Virtually all asphalt maintenance work requires at least a bit of pavement preparation. Sealcoating Austin TX asphalt pavements also requires contractors to prepare the pavement before starting an application. Here are the two biggest pavement preparation mistakes that a seal coating contractor can make.

1. The contractor does not repair pavement damage prior to applying a sealcoat. If the contractor does not repair significant cracks or potholes, applying a sealant is a waste of time and money.

2. The contractor does not clean the pavement thoroughly. To provide proper protection, the sealcoating and the pavement must establish a strong bond. The contractor must remove anything that might interfere with the bonding process. This includes dirt, vegetation, oil spills, loose gravel, and asphalt particles.

What Are Two Common Application Mistakes That an Austin Sealcoating Contractor Might Make?

The application is the most important part of a successful sealcoating job. Although there are several possible application mistakes that a contractor might make, the following two are the most common.

1. The contractor skips priming the pavement. Before applying a sealcoat, the contractor may need to apply a primer to ensure proper bonding. Although not all projects require the use of a primer, many middle-aged or older pavements do. Common locations that often need a primer include oil stains and areas with polished aggregate. Some older, heavily oxidized pavements may even require the application of a primer to their entire surface area.

2. The contractor applies the sealcoating too thickly. When sealcoating parking lots, it is common to apply two coats to the entire pavement. Contractors should never try to speed up the job by applying one thick coat. Thick coats of parking lot sealcoating in Austin may never cure properly, resulting in tracking and sealant loss. Furthermore, each thin coat must dry before the contractor applies the next coat. The final coat must dry before applying line striping and markings, and it must cure before it begins receiving traffic.

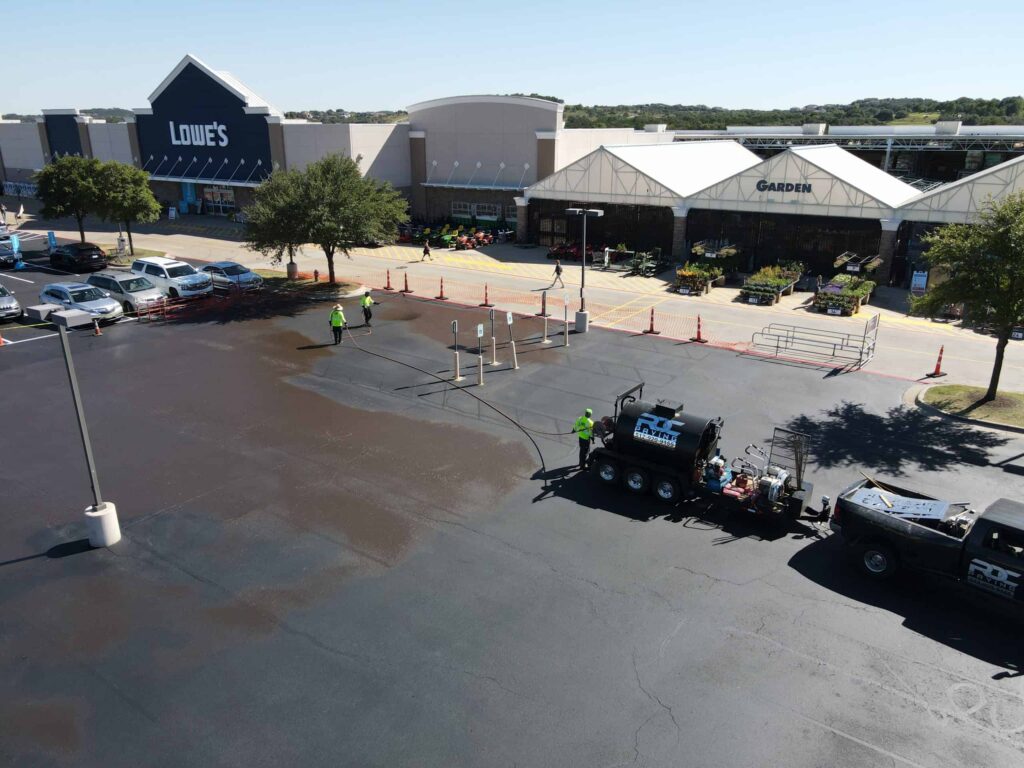

At RDC Paving, we provide asphalt sealcoating for commercial clients with superior results at competitive rates. Our services include sealcoating, residential driveway paving, asphalt overlays, parking lot striping, asphalt paving, parking lot maintenance, asphalt milling and repair, and asphalt crack repairs. We also install and repair concrete. We have exceptionally skilled employees who will deliver extraordinary results and exemplary service. Request a free quote today by either submitting the online form or calling 512-920-9155.